Aldwarke Ladle Lid Trial Lining Case Study

Please find the Aldwarke Ladle Lid Trial Lining case study from SHL Refractories (UK) Ltd.

For more information, details and enquiries regarding this or any of the case studies listed on our website, please Contact SHL Refractories (UK) Ltd.

Telephone: 01909 731959

1. 12.7mm Pirotek tiles.

2. Anchor holes drilled.

3. Steel strengthening rib covered with 13mm blanket / outer rim 3mm ceramic paper, 100mm coated V anchor welded and sectioned into 8 panels.

4. 4 panels cast 140mm thick 4 anchored ready to cast.

5. All 8 panels cast and centre anchored.

6. Casting complete.

7. In oven ready for dry out to 350 deg C

8. Ready for dispatch

Arc Furnace Build Case Study

Please find the Arc Furnace Build case study from SHL Refractories (UK) Ltd.

For more information, details and enquiries regarding this or any of the case studies listed on our website, please Contact SHL Refractories (UK) Ltd.

Telephone: 01909 731959

1. Fit 16mm Pirotec tile to bottom.

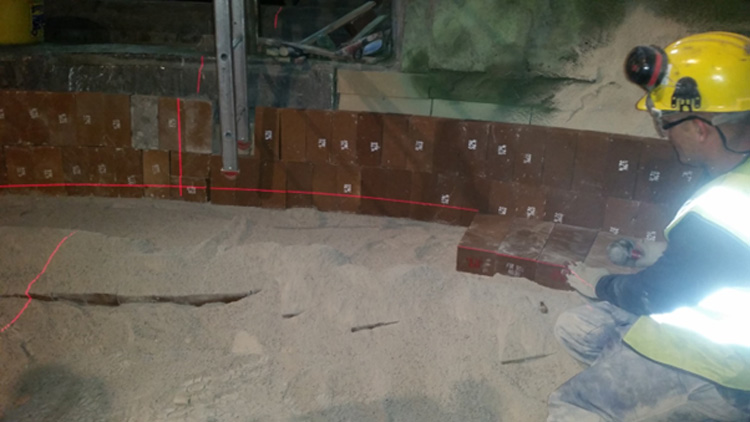

2. Pave IC 92% Mag brick squares parallel with centre line.

3. Lay 2nd course at 90 degrees to 1st.

4. Lay 2nd course with up-stand.

5. Lay 3rd course 45 degrees to 2nd piece up behind up-stand.

6. Set 1st course per mag sub hearth in.

7. Set 2nd and 2rd course sub-hearth.

8. Set 12mm Pirtec tile and 75mm 92% mag.

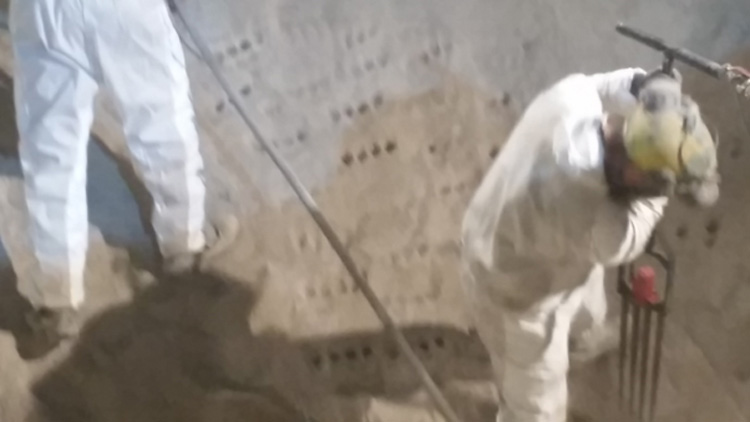

9. Spray over with green to blend in misshaped casting.

10. Fill behind upstand with hearth ramming.

11. 4th courses per mag goes full circle layer to exact level.

12. Course 4 to 9 per mag full circle.

13. Make up tap hole slope and fit block.

14. Fit working platform fill gap with hearth ramming.

15. Working from tap hole block around the furnace.

16. After 6 course, remove working platform. Make sure all paper and debris is removed. Put bag of hearth ramming full circle touching to form shutter and base for platform.

17. Fit working platform on top of bags and fill gap with hearth ramming.

18. Fit delta blank over gap up to tap hole.

19. 12mm tile blister boxes and brick with 92% mag bricks jointed.

20. Spray with green all blister boxes and casting.

21. Fit sill block so jambs can be pieced up to block.

22. Continue with 600mm side walls.

23. Fit N FCE slag cover plate in tap hole.

24. Bomb jamb brickwork.

25. Top 2 course under each water cooled panel reduces to 450mm pressed up tight under panel with 350mm splits.

26. Over spray with green all lining.

27. Clean all green and other debris from top of ramming and working platform.

28. Remove working platforms.

29. Move bags to one side. Start putting ramming in from front of tap hole.

30. After bag in FCE, put around vibro fork until compacted.

31. Put rest of ramming into position and vibro fork again then vibro sledge.

32. When complete, fit sacrificial 2mm plates over ramming for protection from first scrap basket.

33. Complete.