SHL Refractories (UK) Ltd. are leading U.K. experts for nationwide refractory installation, providing a range of associated services covering: Workshop Facilities, Portable Drying System & Drying Facilities, Installation Services and Refractory Lining Demolition. Our services are available to industry sectors including, but not limited to:

Iron & Steel • Power Generation • Aluminium Industry • Incineration • Petro-Chemical • Sugar Industry • Gypsum Industry • Lime Industry • Cement Industry • Pottery and Brick • Acid Production • Plants Titanium Oxide Plants • Food Chemical Plants • Hospitals

Workshop Facilities

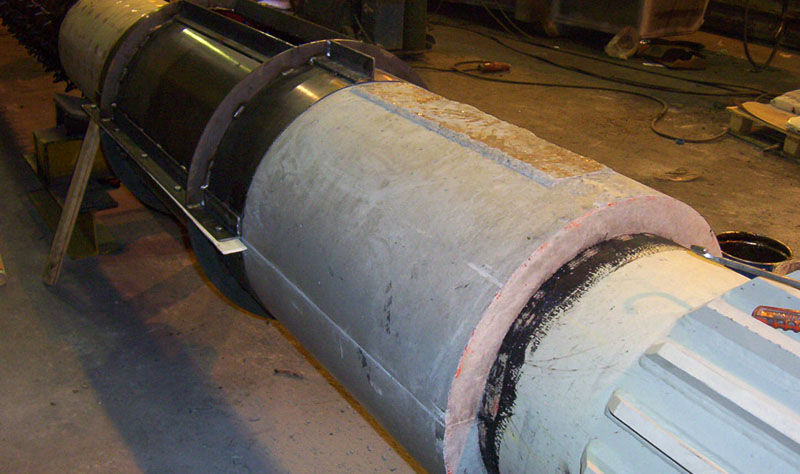

The fully equipped workshop situated at the Carlton-in-Lindrick, Worksop site provides the opportunity for SHL Refractories (UK) Ltd. to offer a total package to its customers. The workshop is complete with a 25 tonne crane and drying oven. In addition to casting special purpose blocks, shapes, burner quarls etc., large units, such as ladles, tundishes, chimney sections and even complete furnaces can be refractory lined in-house. Not only by the production of various types of pre-cast items in the workshop but also providing essential back up to the SHL installation services on customers sites. Other facilities include…

- Large, fully automatic drying oven.

- Large stock of refractory materials.

- Joinery facilities for the manufacture of moulds and formers.

- Welding facilities for anchors and steelworks, fabrication/repairs.

- Shotblast Services.

For more information regarding our workshop facilities, please…

Contact SHL Refractories (UK) Ltd

Telephone: 01909 731959

Portable Drying System &

Drying Facilities

The workshop is also equipped with a portable drying system providing greater flexibility for drying a variety of work. This results in improved drying availability and therefore a much quicker turn round time for all work, ranging from full turn key projects involving wrecking and installation of full refractory linings through to small pre-cast items. This dryer can be used for curing refractory linings in tundishes, ladles, chimney/ducting, sections, furnaces etc which require precise temperature control for accurate ramp and soak programs which will in turn prolong the life of the installed refractory.

With its own drying facilities installed to meet most of the drying requirements for work carried out (which includes, various pre-cast shapes, tundishes, ladles, chimney sections and even complete furnaces) the workshop can supply a project with the refractory lining fully dried and ready for service on the customer’s site. The drying facilities include a fully automatic drying oven capable of holding items up to approximately 6 metres long and a portable drying system which offers a more versatile alternative for the various projects undertaken.

With these two systems available in the workshop SHL Refractories (UK) Ltd are able to provide the precise temperature control to achieve the accurate drying temperature profiles required to maximise refractory performance.

For more information regarding our portable drying System & drying facilities, please…

Contact SHL Refractories (UK) Ltd

Telephone: 01909 731959

Installation Services

SHL has an excellent reputation for being one of the leading refractory installation companies in the UK and cover a wide spectrum of industries including:

- Iron and Steelwork.

- Aluminium.

- Incineration.

- Petro-Chemical.

- Pottery and Brick.

- Power Generation.

- Lime and Cement.

- Gypsum.

- Food.

- Hospital.

- Local Government.

- Chemical.

Site operations represent the majority of the contracts undertaken and this is supported by a fully equipped factory workshop, complete with a 25 tonne overhead crane and drying oven, for the production of special shapes, blocks, burner quarls, etc. Larger units such as ladles, tundishes, chimney sections and even complete furnaces can be refractory lined in-house.

We employ a highly experienced team of managers, engineers, supervisors and tradesmen and offer a service 7 days per week, 24 hours per day.

For more information regarding our installation services, please…

Contact SHL Refractories (UK) Ltd

Telephone: 01909 731959

Refractory Lining

Demolition

Refractory linings demolished with ease and in complete safety. Our new remotely controlled machines can be used for many different demolition processes within the refractory industry.

| Brokk 50 | |

| Transport Length (exc.attachments) | 1380mm |

| Transport Height | 940mm |

| Transport Width | 600mm |

| Working Radius | 2400mm |

| Weight (exc. Attachments) | 475kgs |

| Electrical Connection | 415 volt x 16 Amp Supply |

| Brokk 90 | |

| Transport Length (exc.attachments) | 1600mm |

| Transport Height | 1285mm |

| Transport Width | 780mm |

| Working Radius | 3000mm |

| Weight (exc. Attachments) | 980kgs |

| Electrical Connection | 415 volt x 32 Amp Supply |

| Brokk 150 | |

| Transport Length (exc.attachments) | 2340mm |

| Transport Height | 1245mm |

| Transport Width | 1130mm |

| Working Radius | 3500mm |

| Weight (exc. Attachments) | 1750kgs |

| Electrical Connection | 415 volt x 63 Amp Supply |

| Brokk 180 | |

| Transport Length (exc.attachments) | 2489mm |

| Transport Height | 1392mm |

| Transport Width | 1200mm |

| Working Radius | 4000mm |

| Weight (exc. Attachments) | 1930kgs |

| Electrical Connection | 415 volt x 63 Amp Supply |

For more information regarding our refractory lining demolition services, please…

Contact SHL Refractories (UK) Ltd

Telephone: 01909 731959

Iron and Steel

SHL service the iron and steel industry by providing first class refractory installations from the melting shop right through to the re-heating and heat treatment furnace. SHL can offer full turn-key steel plant installation contracts and can provide 24 hours manning, 7 days per week. Services include re-line and repair of:

- Transfer and Teeming Ladles.

- Secondary Steel Making Ladles.

- Electric Arc Furnaces.

- A.O.D. Vessels.

- Con-cast Tundishes.

- A.O.D. Fume Hood Linings.

- Soaking Pits.

- Re-Heat & Heat Treatment Furnaces.

For more information regarding our Iron and Steel services / facilities, please…

Contact SHL Refractories (UK) Ltd

Telephone: 01909 731959

Incineration Industry

SHL has an excellent reputation for refractory installation covering a wide spectrum of incineration plants, furnaces, primary and secondary combustion chambers, flue ducts and chimneys. We employ a highly experienced team of managers, engineers, supervisors and tradesmen and offer a service 7 days per week, 24 hours per day.

- Domestic Refuse – Municipal Incineration.

- Clinical Incineration.

- Animal Carcass Incineration.

- Liquid & Solid Waste Incineration.

- Human Cremators.

- Fired Heaters.

- Water Tube Boilers.

- Steam Raising Boilers.

For more information regarding our Incineration Industry services / facilities, please…

Contact SHL Refractories (UK) Ltd

Telephone: 01909 731959